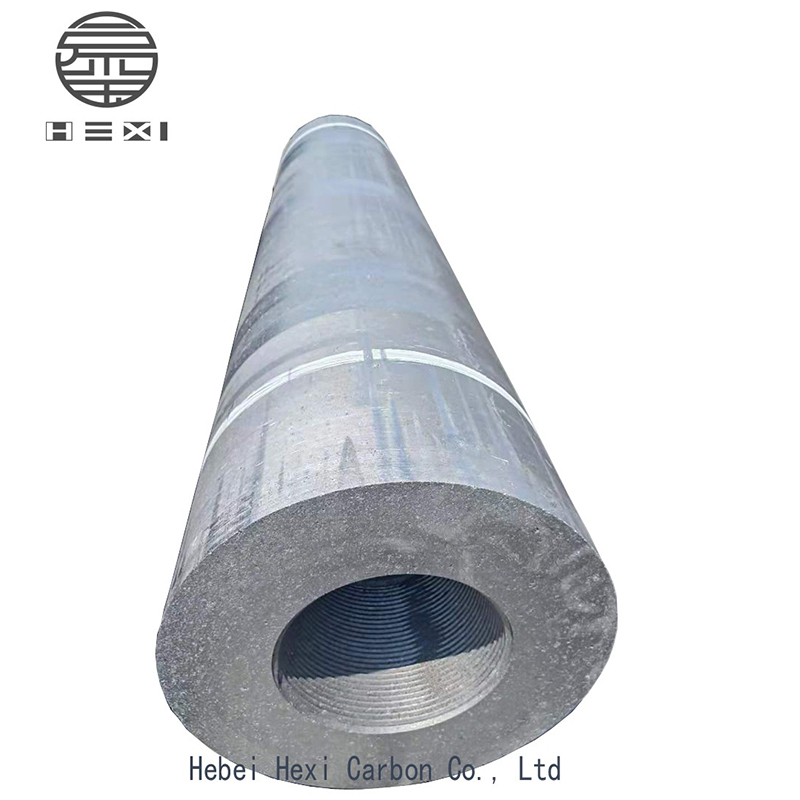

450mm amandla aphezulu egraphite electrod

I-electrode yegraphite ye-HP yenziwe ikakhulu ngepetroleum coke kunye nenaliti yecoke, Iyakwazi ukuthwala ukuxinana kwangoku 18-25A/cm2. Yenzelwe ukwenza intsimbi yesithando sombane esinamandla aphezulu.

| Uthelekiso lobuChwephesha beNkcazo ye-HPI-Graphite Electrode18″ | ||

| I-Electrode | ||

| Into | Iyunithi | Supplier Spec |

| Iimpawu eziqhelekileyo zePole | ||

| Idayamitha yeNominal | mm | 450 |

| Ubukhulu beDayamitha | mm | 460 |

| Ububanzi obuncinci | mm | 454 |

| Ubude begama | mm | 1800-2400 |

| Max Ubude | mm | 1900-2500 |

| Min Ubude | mm | 1700-2300 |

| Unizi lolwapho kuyiwa khona | g/cm3 | 1.68-1.73 |

| amandla anqamlezileyo | MPa | ≥11.0 |

| Omncinci' uModulus | GPA | ≤12.0 |

| Ukuchasa ngokuthe ngqo | µΩm | 5.2-6.5 |

| Ubuninzi bangoku | KA/cm2 | 15-24 |

| Umthamo wokuthwala wangoku | A | 25000-40000 |

| (CTE) | 10-6℃ | ≤2.0 |

| umxholo wothuthu | % | ≤0.2 |

| Iimpawu eziqhelekileyo zengono (4TPI/3TPI) | ||

| Unizi lolwapho kuyiwa khona | g/cm3 | 1.78-1.83 |

| amandla anqamlezileyo | MPa | ≥22.0 |

| Omncinci' uModulus | GPA | ≤15.0 |

| Ukuchasa ngokuthe ngqo | µΩm | 3.5-4.5 |

| (CTE) | 10-6℃ | ≤1.8 |

| umxholo wothuthu | % | ≤0.2 |

Indlela yokunciphisa ukusetyenziswa kwe-electrode

Kwiminyaka yakutshanje, kunye nophuhliso olunamandla loshishino lwentsimbi yaseTshayina yeziko lombane, kunye neemfuno zokonga amandla kunye neengcali zokunciphisa ukusetyenziswa kunye nabaphengululi ekhaya nakwamanye amazwe baqukumbela ezinye iindlela ezisebenzayo ngolu hlobo lulandelayo:

1.I-Anti-oxidation mechanism of water spray graphite electrode

Ngophando lovavanyo, ukutshiza isisombululo se-anti-oxidation kumphezulu wee-electrode kubonakalise ngcono kakhulu ekumiseni ukusuka kwicala le-oxidation ye-graphite electrode, kwaye amandla okulwa ne-oxidation anyuka ngamaxesha angama-6-7. Emva kokusebenzisa le ndlela, ukusetyenziswa kwe-electrode kuye kwehla ukuya kwi-1.9-2.2kg yokunyibilikisa itoni yentsimbi.

2.I-electrode eHollow

Kwiminyaka yakutshanje, iNtshona Yurophu neSweden ziye zaqalisa ukusebenzisa i-electrode engenanto xa kuveliswa iziko lentsimbi ekrwada ye-ferroalloy. Ii-electrode eziHollow, imilo yesilinda, zihlala zingenanto ngaphakathi zitywinwe ngegesi engasebenziyo. Ngenxa yobunzulu, iimeko zokubhaka ziyaphucuka kwaye zenza amandla e-electrode abe phezulu. Ngokuqhelekileyo, inokugcina i-electrodes ngama-30% -40%, ukuya kuma-50% kakhulu.

3.DC isithando somlilo

I-DC electric arc furnace luhlobo olutsha lwesithando sombane esinyibilikisayo esandula ukuphuhliswa kwihlabathi kwiminyaka yakutshanje. Ukusuka kwidatha epapashwe phesheya, i-DC arc furnace yenye yezona ndlela zisebenzayo zokunciphisa ukusetyenziswa kwe-electrode. Ngokuqhelekileyo, ukusetyenziswa kwe-electrode kungancitshiswa malunga ne-40% ukuya kwi-60%. Ngokweengxelo, ukusetyenziswa kwe-electrode yegraphite ye-DC enkulu ye-ultra-high power furnace yombane iye yancitshiswa yaba yi-1.6kg / t.

I-4.Ubuchwephesha bokugquma ubuso be-Electrode

Itekhnoloji yokwambathisa i-Electrode yitekhnoloji elula nesebenzayo yokunciphisa ukusetyenziswa kwe-electrode, ngokuqhelekileyo inokunciphisa ukusetyenziswa kwe-electrode malunga ne-20%. Izinto ezisetyenziswa ngokuqhelekileyo zokugquma i-electrode ziyi-aluminium kunye nezixhobo ezahlukeneyo ze-ceramic, ezinokumelana ne-oxidation eqinile kumaqondo aphezulu kwaye inokunciphisa ngokufanelekileyo ukusetyenziswa kwe-oxidation ye-electrode side surface. Indlela yokugcoba i-electrode ikakhulu ngokutshiza kunye nokugaya, kwaye inkqubo yayo ilula kwaye kulula ukuyisebenzisa. Yeyona ndlela isetyenziswa ngokuqhelekileyo yokukhusela i-electrode.

5.I-electrode efakwe ngaphakathi

Dip electrode kwisisombululo sekhemikhali ukubangela ukusebenzisana kweekhemikhali phakathi kwendawo ye-electrode kunye nee-arhente zokuphucula ukuxhathisa kwe-electrode kwi-oxidation ephezulu yobushushu. Olu hlobo lwee-electrode lunokunciphisa ukusetyenziswa kwe-electrode malunga ne-10% ukuya kwi-15%.